"i-CAN" "i-DO" modular control system: Modular design on host system, valve component and material receiver parts. Modular units forming a conveying network system in flexible way, easy for upgrading, high intelligent mode

Strictly stick to the concept of "products are works of art", The well-designed system equipped with world-class components, therefore, guarantee high reliability and perfect performance of each function in purpose

Energy saving and environmental protection: Mute mode / low noise, auto-dust remove, flexible power pump options, efficacy eco-friendly product spirit going all throughout from beginning of design to the final step of operation

Experienced design capability for large and complex system: professional & experienced structural design engineers, software engineers, electrical engineers, field application engineers co-work out advanced and cost-effective solutions for clients

Worry-free service: Company owned professional construction team, with years of field experience, good at each single detail issue handling, high efficiency on site to bring clients’ a artwork of conveying system

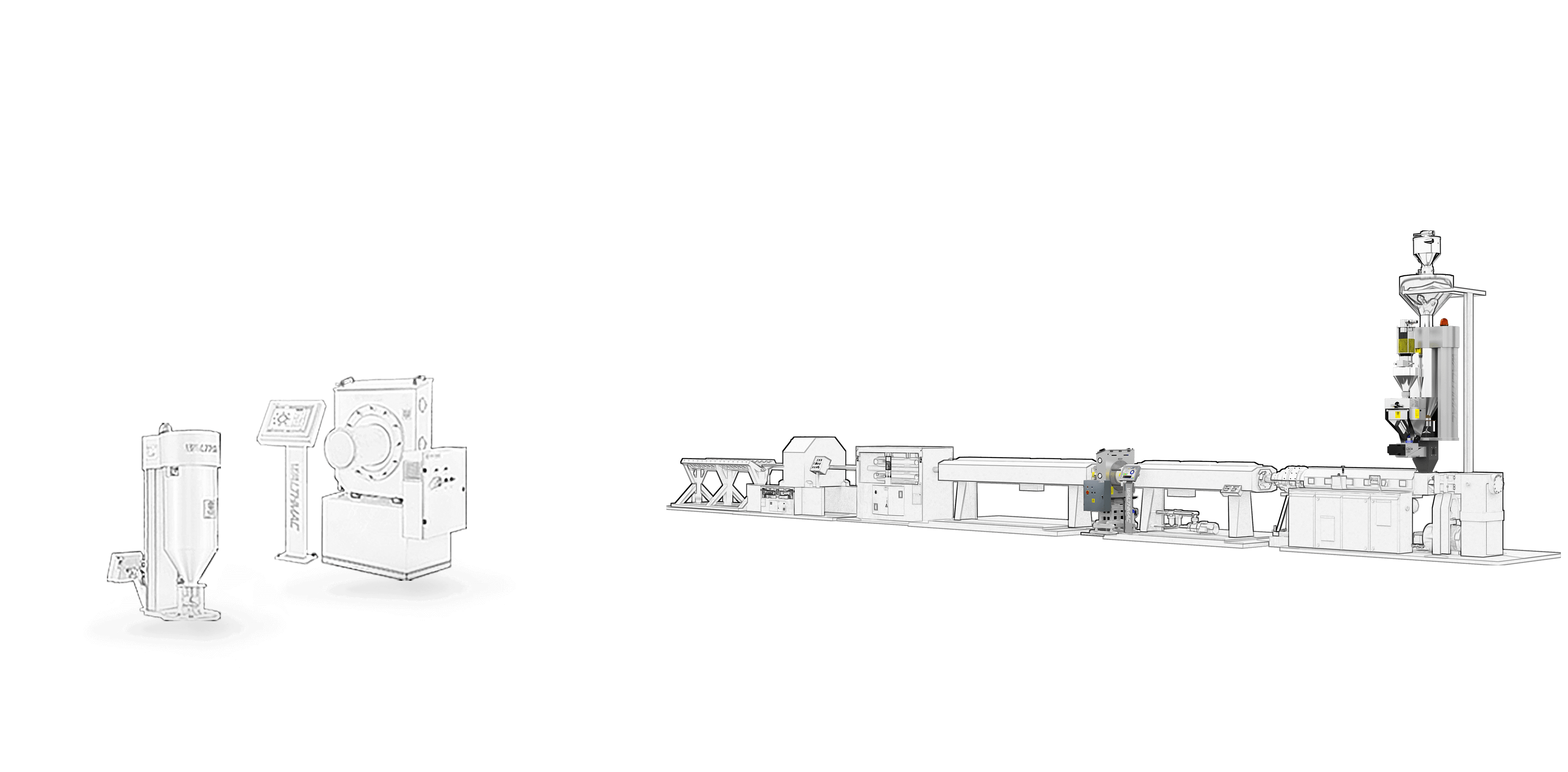

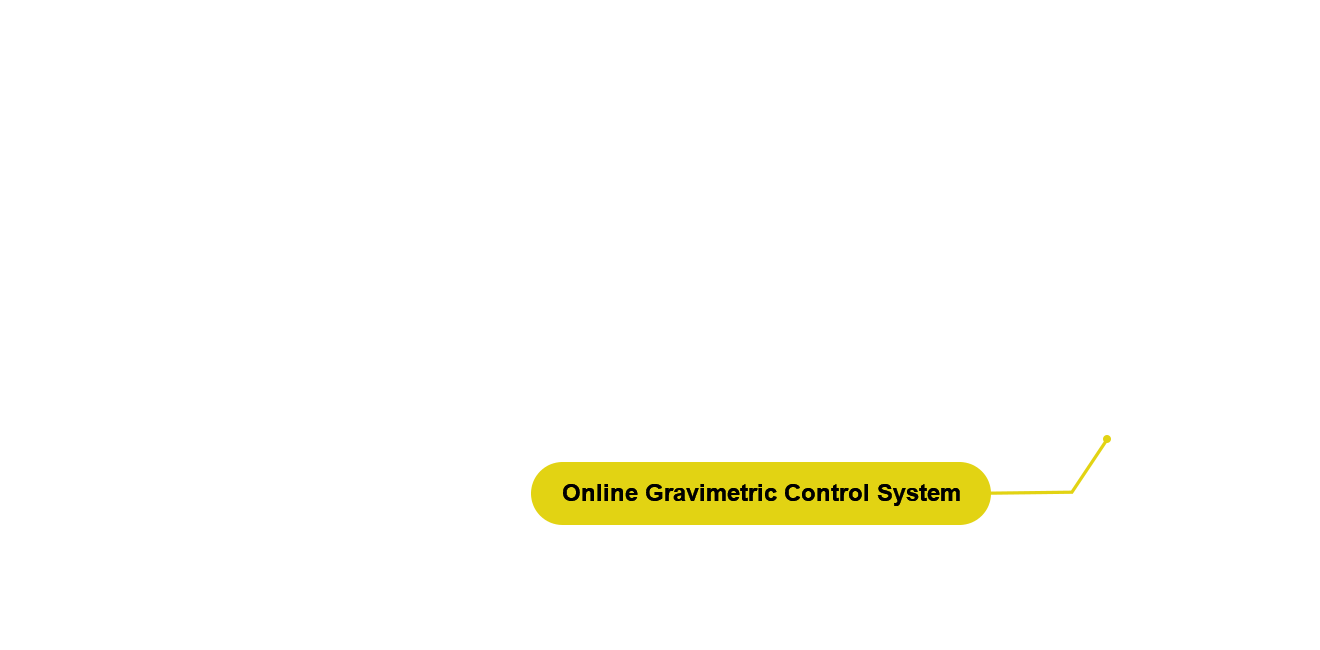

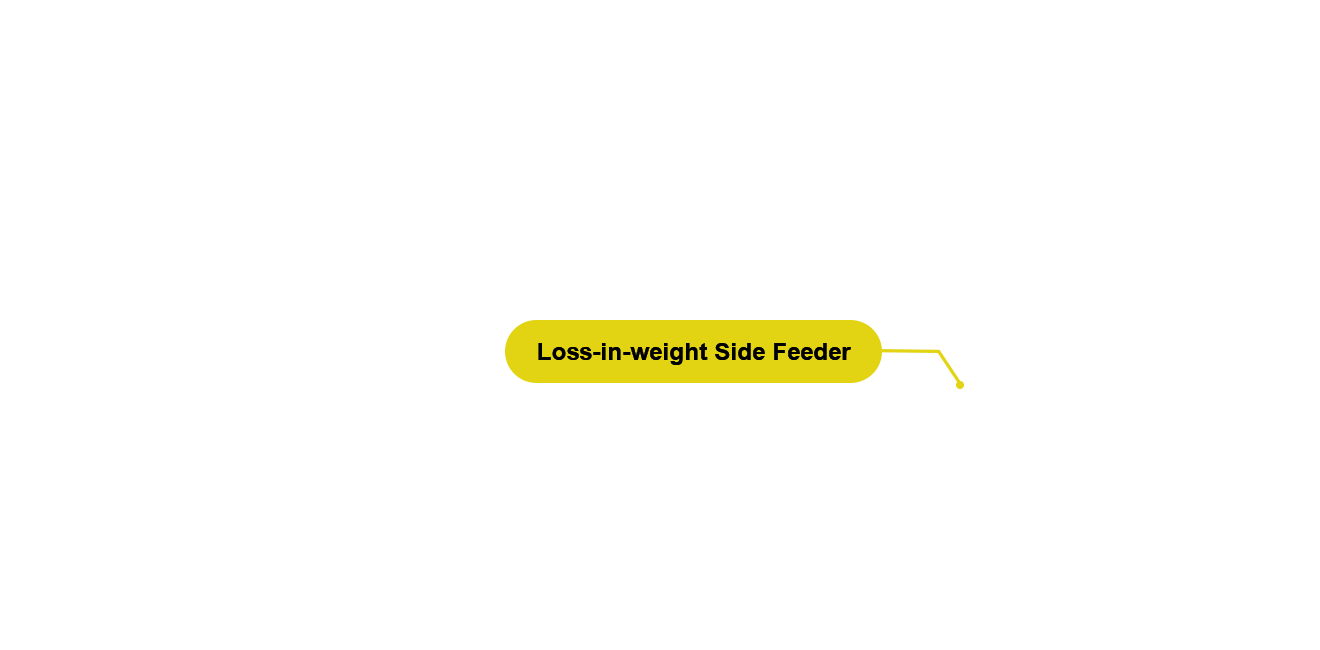

Airflow source | Control center | System Control Mode | Fixed Supportor | Silencing component | Material Receiver | Pipe Line |

High pressure vortex blower | PLC Control system | Switch | Hanging Bracket | Silencer | Stainless steel type | Flexible pipe |

Roots blower | i-CAN control system | Wired network | Combination fixing device | Pipe insulation | Electronic eye type | Galvanized steel pipe |

Roots vacuum pump | Wireless network | Power center mute module | Visual model | Stainless stell pipe | ||

| Customizing | Glass pipe | |||||

Special plastic pipe |

中文

中文 English

English Español

Español Русский

Русский