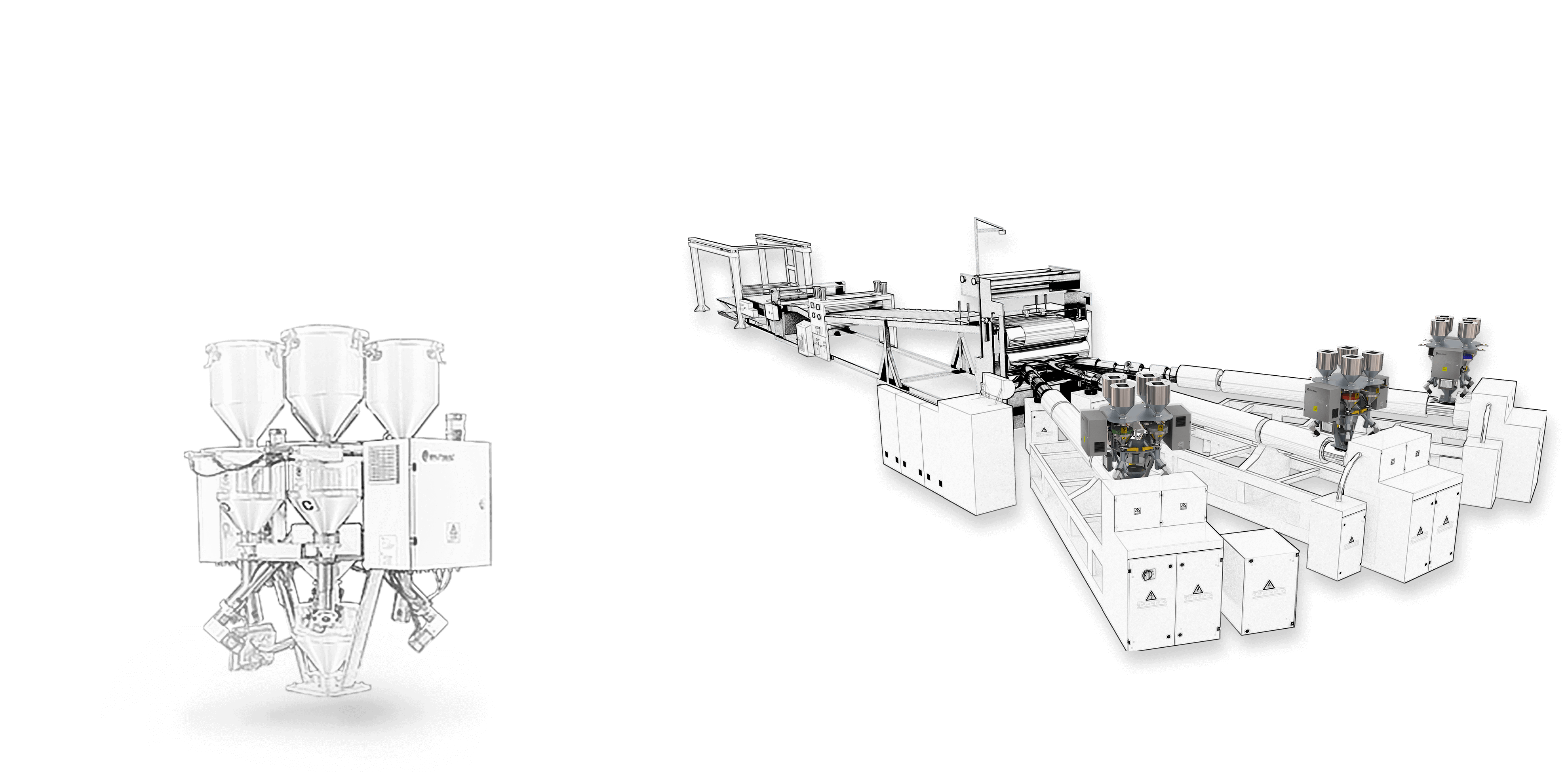

Control the extrusion output and the weight of meter to stabilize the product quality;

Shorten start-up time, save raw materials, and reduce dependence on the experience, skills and luck of production line operators;

Raw material saving up to 1-5%, production increase up to 5%;

Product control accuracy is less than +/-0.5%;

Continuous raw material saving, the fastest 2 months to recover investment *;

Full automatic control;

7 inch TFT touch display, control process dynamic display;

The improved material feeding structure is specially used for the good fluidity material;

Automatic compensation for material density accumulation caused by changes;

Quick release structure of weighing hopper;

Visualization of blanking port;

Quick replacement of all parts;

Network co-extrusion, remote control or data acquisition.

Model | Height (mm) | Output(kg/h) |

GMSF-500N | 910 | 50-500 |

GMSF-900N | 1020 | 50-900 |

GMSF-1200N | 1200 | 100-1200 |

GMSF-1600N | 1450 | 100-1600 |

中文

中文 English

English Español

Español Русский

Русский