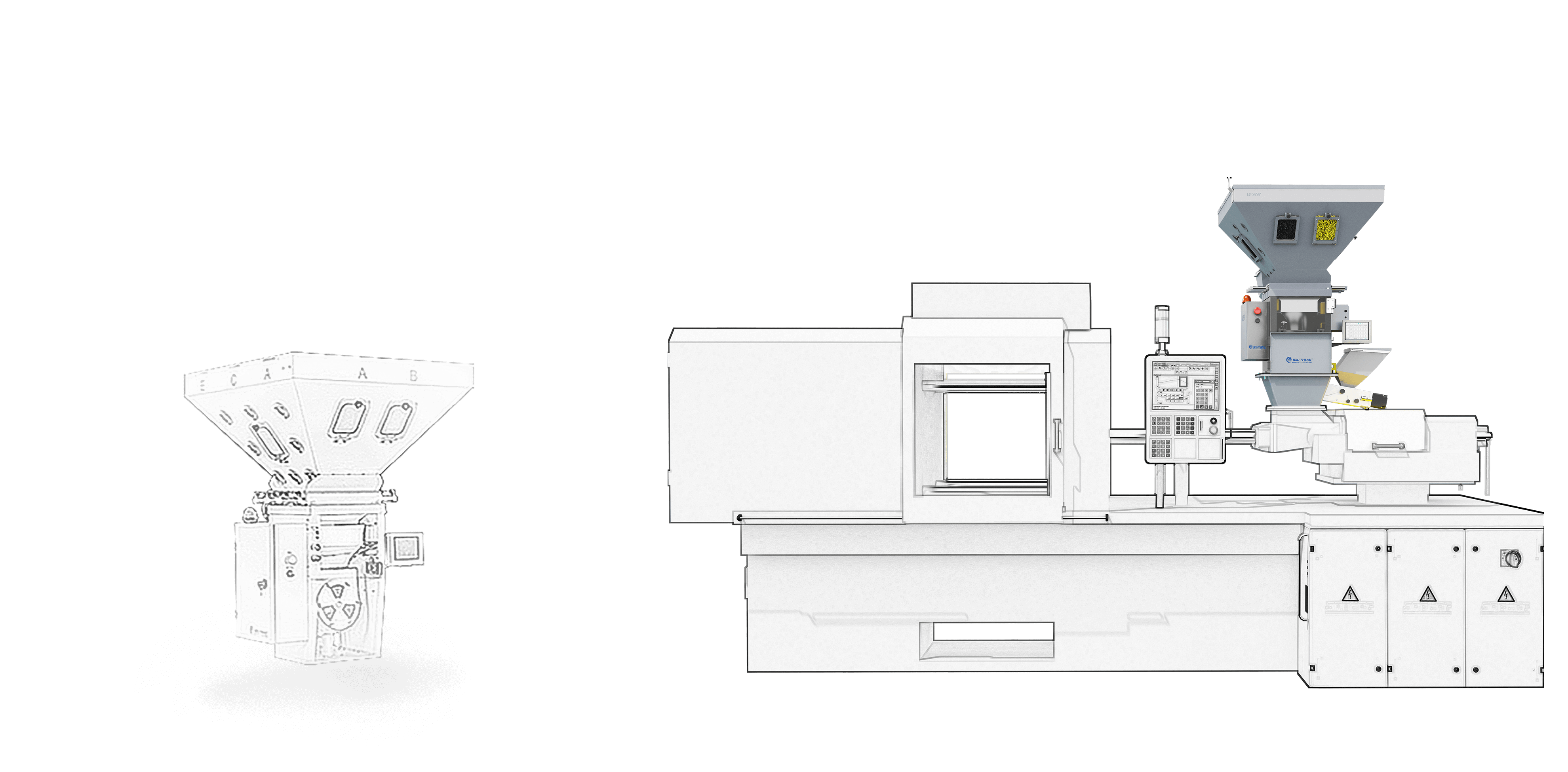

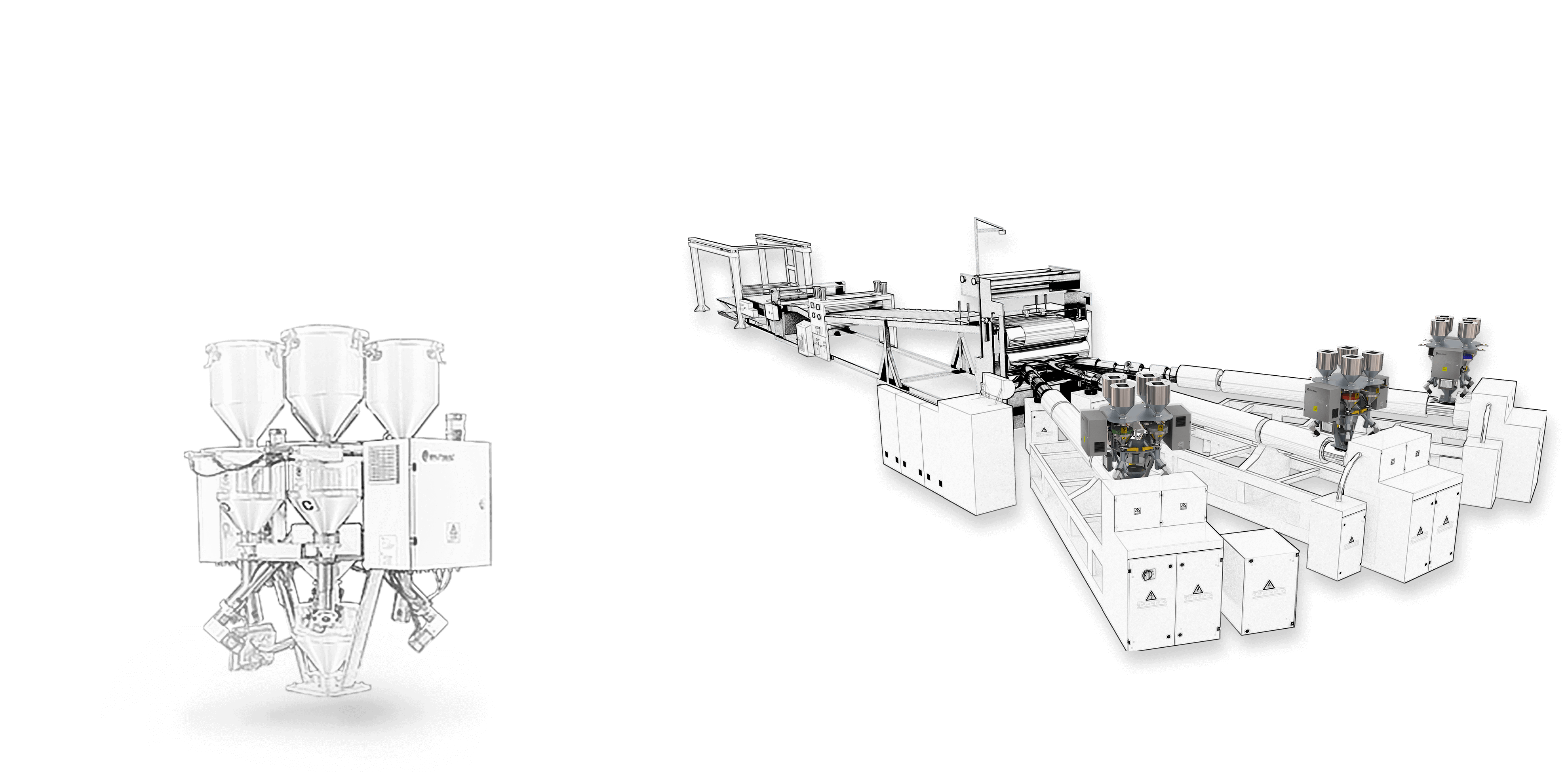

WBB-H Series

Modular design, detachable structure, free-tool maintenance, easy operation;

Max Components: 6, Maximum throughput: 2600KG/H;

Multiple dosing modes are applicable for varied applications and to guarantee accurate proportion;

10”true color of touch screen with multi-language choices, dynamic and colorful diagram display;

Adopting advanced self-adaptation control algorithm, error self-correcting to each single batch, dosing precision can be optimized even under vibration based on unique anti-vibrating structure and algorithm;

USB access and Ethernet port, support MODBUS-TCP and remote data transmission and update;

Imported energy conservation motor;

Alarm will caution for record handling and output;

Made of stainless steel 316, Surface treatment: sand blasting;

Weighing and stirring are visible, simple and direct;

Feeding/dosing error*: <0.1%(Unique error calculation and measurment methods based on industry and WalthMac);

Metler-Toledo or HBM load cell with high precision;

Resolution of weigh signal is as high as 4,000,000:1;

Remote control function (option);

Grading password control, alarm records and save function for max. 100 groups of formula saving;

Function of throughput statistics;

Installation on-line through the adaptor or off-line nearby the master machine through the platform.

WBB-H Series

Component quantity | Batch weight(kg) | Model | Max. output (kg) | Size (mm) | Consumption (w) |

2 | 1 | WBB-H-01/02 | 135~245 | 450*400*1300 | 150 |

2 | WBB-H-02/02 | 285~360 | 500*500*1500 | 250 | |

4 | 1 | WBB-H-01/04 | 110~160 | 750*750*1300 | 150 |

2 | WBB-H-02/04 | 240~300 | 750*700*1500 | 250 | |

4 | WBB-H-04/04 | 410~500 | 800*800*1650 | 400 | |

8 | WBB-H-08/04 | 800~1000 | 850*800*1850 | 600 | |

12 | WBB-H-12/04 | 1200~1400 | 850*850*1950 | 800 | |

20 | WBB-H-20/04 | 2000~2400 | 950*950*2150 | 1100 | |

30 | WBB-H-30/04 | 3000~3600 | 1050*1050*2150 | 1500 | |

40 | WBB-H-40/04 | 4000~4800 | 1150*1150*2200 | 2000 | |

6 | 1 | WBB-H-01/06 | 85~120 | 850*800*1300 | 150 |

2 | WBB-H-02/06 | 175~220 | 850*800*1500 | 250 | |

4 | WBB-H-04/06 | 300~400 | 950*900*1850 | 400 | |

8 | WBB-H-08/06 | 530~650 | 950*900*1850 | 600 | |

12 | WBB-H-12/06 | 800~960 | 1200*1100*1950 | 800 | |

20 | WBB-H-20/06 | 1330~1600 | 1200*1100*1950 | 1100 | |

30 | WBB-H-30/06 | 2000~2400 | 1300*1200*2200 | 1500 | |

40 | WBB-H-40/06 | 2700~3200 | 1350*1250*2300 | 2000 |

中文

中文 English

English Español

Español Русский

Русский