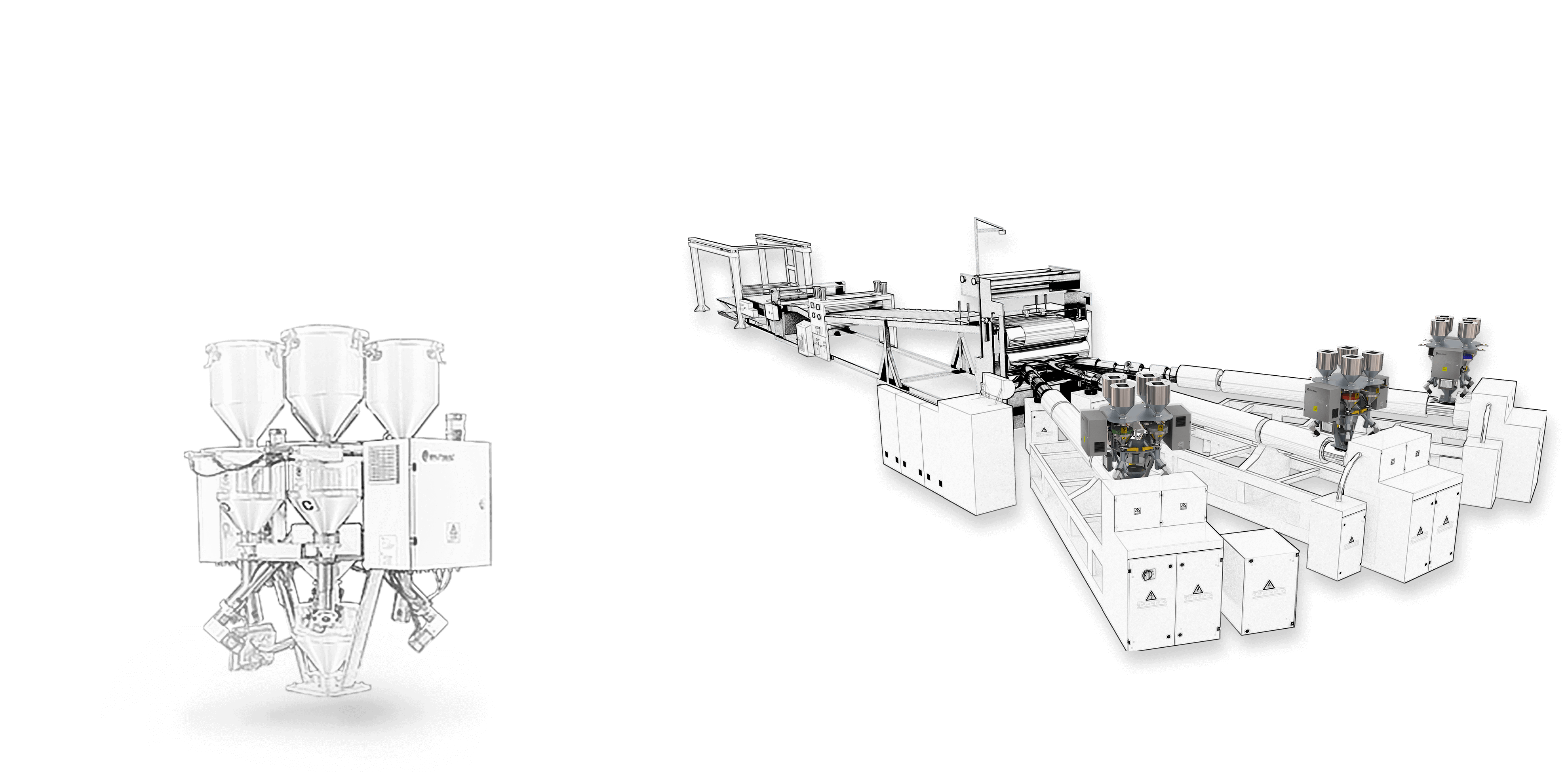

Automatic material filling;

High precision weightless measuring system;

Screw feeding is suitable for a variety of materials;

Servo system closed loop control, fast reaction speed;

Touch screen operation and dynamic flow ratio model make operation more convenient;

Formula can be changed in real time, rice weight and extrusion control function are optional;

Mixing precision error :<0.5%, mixing precision error :< 0.1%.

Model | Max. output (kg/h) | No. Components | Size (mm) |

WCB-180/G | 180 | 1~4 | 700*700*1020 |

WCB-300/G | 300 | 1~4 | 850*850*1240 |

WCB-600/G | 600 | 1~4 | 950*950*1560 |

WCB-1200/G | 1200 | 1~4 | 1150*1050*1680 |

Note: /G is the control function with meter weight, and the actual output is related to raw materials and components based on the measurement of specific component quantity and method based on WTH。 | |||

中文

中文 English

English Español

Español Русский

Русский